Electroslag Furnace is a special smelting equipment that uses the heat generated by remelting current to melt the self-consuming electrode inserted into the slag pool. The metal melt droplets pass through the slag liquid cleaning and then crystallize into electroslag ingots in the water-cooled crucible. Due to the deslagging effect of the slag liquid and good crystallization conditions, electroslag remelted metal has good purity, fine and uniform cast structure, no white spots and annual ring-like segregation, extremely low sulfur content, and fine and dispersed inclusions. Therefore, electroslag remelting occupies a dominant position in the production of large and medium-sized forgings and module blanks, and has an absolute advantage in high-quality tool steel, martensitic age-hardening steel, duplex pipe billets, cold rolling mill roll electroslag steel, corrosion-resistant alloys, and high-temperature alloys. The annual output of electroslag steel in China has reached hundreds of thousands of tons, and electroslag furnaces are essential special smelting production equipment for special steel plants.

To prevent the influence of the atmospheric environment on the changes of elements during the smelting process, modern electroslag remelting furnaces are basically all smelted in an inert gas environment to prevent the oxidation and burnout of the remelted metal. This is the greatest technological progress of static smelting electroslag remelting furnaces in the past decade.

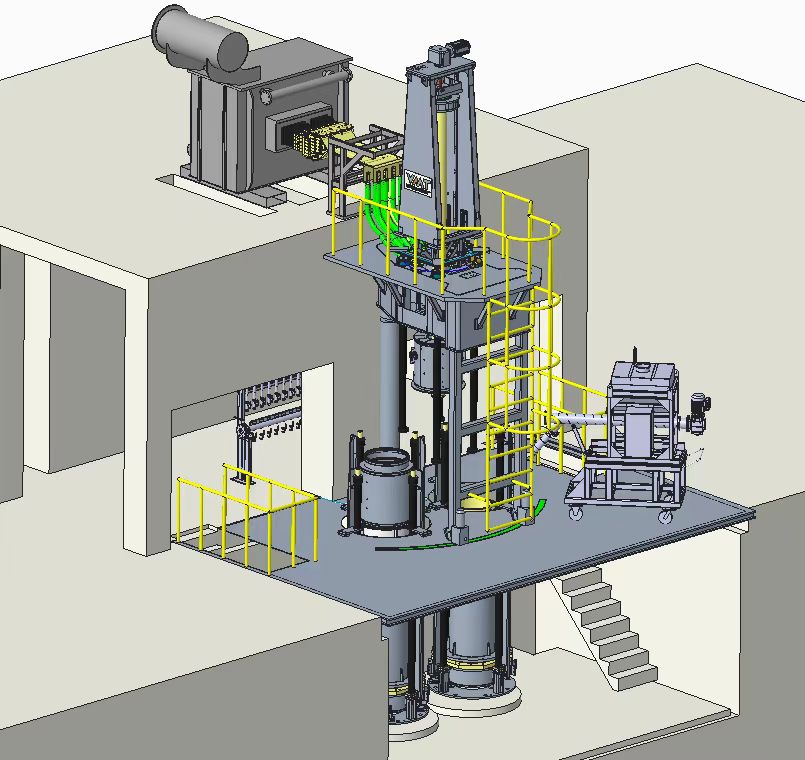

VMT's ESR furnace adopts the world's most advanced fully coaxial conductive technology, constant melting speed control technology, and inert gas protection technology. Through an advanced automatic smelting control system and high-precision weighing system, it achieves precise control of the depth of the self-consuming electrode inserted into the slag pool, thereby achieving constant melting speed control of the self-consuming electrode, and ultimately achieving the stability of the entire metal melting pool, which will ensure the stable and reliable quality and reproducibility of the electroslag steel ingot. The ESR furnace designed with fully coaxial conductive technology not only significantly reduces the impedance of the conductive circuit, thereby greatly reducing the energy consumption per ton of steel, but also greatly reduces the stirring effect of the magnetic field on the metal melting pool, thereby reducing the probability of segregation in the steel ingot.

VMT's fully automatic control system not only absorbs the advantages of the control systems of international advanced ESR furnace suppliers but also carries out a large number of innovative optimization designs based on digestion and absorption. Especially in the design of PID control and melting speed control, VMT. adopts more advanced algorithms to ensure that the control system is more sensitive and accurate, ultimately achieving more stable, reliable, and reproducible performance of the smelted electroslag steel. The entire control system consists of a lower machine PLC and an upper machine HMI. The PLC not only controls all mechanical and electrical actuator actions of the furnace but also controls the entire smelting process. The PLC mainly achieves constant melting speed control of the self-consuming electrode through pressure swing control and weighing system, and the control of the pressure swing amount can well control the depth of the self-consuming electrode inserted into the slag pool, thereby well controlling the state of the melting pool. The upper machine HMI only serves as an operation interface to view, create, store, and analyze remelting data and production curves.

VMT's melting power supply system adopts thyristor voltage regulation power supply technology, which has been practiced by internationally renowned peers for many years and has proven its stability and reliability during operation. The incoming voltage of the power supply can be 6kV, 10kV, or 35kV, and the maximum melting current of a single power supply can reach 45,000A. Special melting power supplies can also be customized according to customer specifications.

| category | 500mm | 640mm | 800mm | 900mm | 1,000mm | 1,100mm | 1,250mm | 1,500mm | 1,900mm |

| Spindle weight | 3,000kg | 5,000kg | 10,000kg | 15,000kg | 20,000kg | 30,000kg | 35,000kg | 50,000kg | 150,000kg |

| Crystallizer diameter | 517mm | 660mm | 823mm | 925mm | 1,027mm | 1,130mm | 1,280mm | 1,530mm | 1,940mm |

| Material rod stroke | 2,300mm | 2,300mm | 2,300mm | 2,300mm | 2,300mm | 2,300mm | 2,300mm | 2,300mm | 2,300mm |