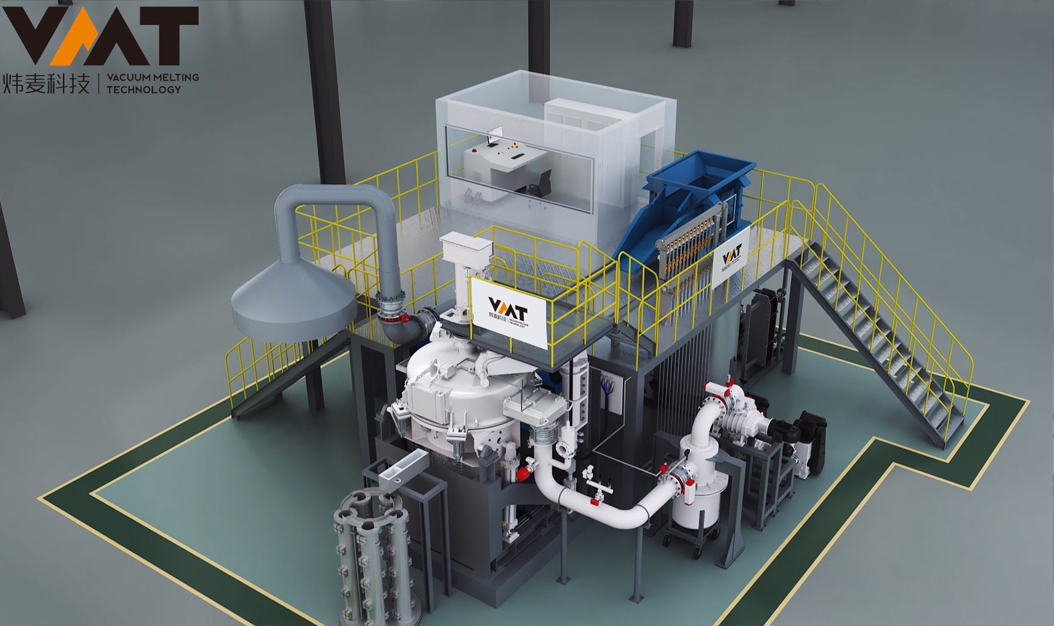

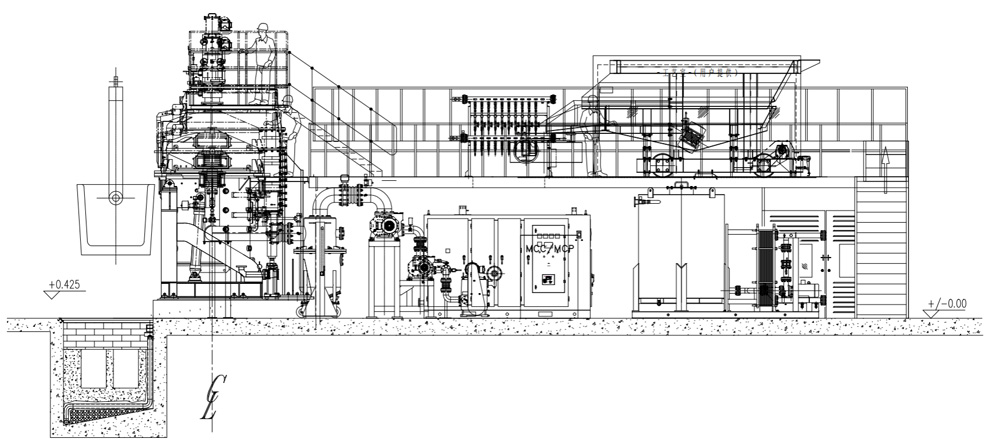

Induction Melting Vacuum Degassing Furnace (IMVD) is developed for special applications in the black and non-ferrous metal industry, which can replace traditional refining furnaces such as LF furnaces, VD furnaces, and VOD furnaces. The maximum design capacity can reach 30 tons. This furnace type is mainly used by small steel mills or foundries to produce small batches and a variety of high-quality alloy materials. Induction melting vacuum degassing furnace (IMVD) refers to the equipment that melts solid metal materials in the atmosphere (or vacuum) by induction melting, refines the molten liquid metal in a vacuum environment by stirring, top blowing oxygen, and bottom blowing argon, and finally pours under atmospheric or inert gas protection.

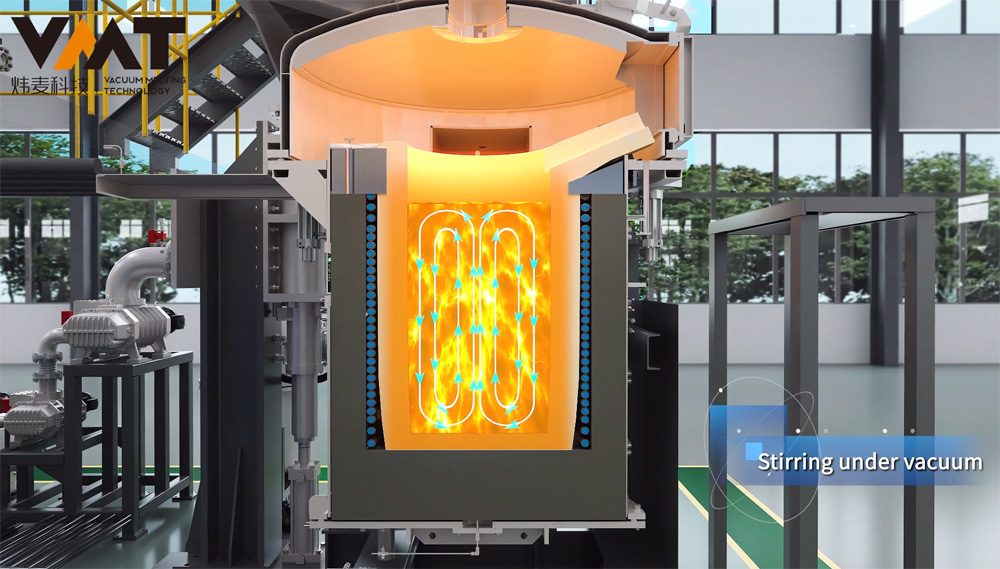

After melting metal in the atmosphere (or vacuum/inert gas) environment, the water-cooled furnace cover is fixed to the top of the induction furnace body to form a vacuum-sealed chamber. A heat-resistant sealing ring is used between the top of the induction furnace body and the water-cooled furnace cover, and the side interface of the furnace cover is directly connected to the multi-stage vacuum system. After starting the vacuum system for evacuation, the entire sealed chamber obtains a high vacuum environment.

| 0.5T | 1.5T | 3T | 6T | 8T | 12T | 20T | 24T | 30T | |

| Furnace type | Rotating lid type | Horizontal moving cover type | |||||||

| pouring weight | 0.5T | 1.5T | 3T | 6T | 8T | 12T | 20T | 24T | 30T |

| Mold drive method | Die plate rotation drive | ||||||||

| Feeding method | Adding ingredients | ||||||||

| Standard melting power | 500KW | 750KW | 1500KW | 3000KW | 4000KW | 5000KW | 8000KW | 10000KW | 15000KW |